Digging around in the engine bay I found both of these. Jammed into the engine mounts. It looks like someone kept dropping and replacing their oil caps. lol I don't know how many years this car was carrying around 3 different oil caps.[/caption]

Put a new distributor O-ring in today. It's been many years since I actually timed a vehicle myself. Don't worry, I can design 3 piece wheels to near exact manufacturing requirements, but timing an old carb'd car isn't common knowledge to me. Took a lot of fiddling around to get it to 12 degrees advance without vacuum advance plugged in. Why so tough for me?! I did some other things like tighten up the parking brake tension, adjust the wheel straight, and pack the car for tomorrow. We'll give it a try! Still have the big suspension install to go, and I've got some new parts coming too, like a racing seat and a rear sway bar. Score! Thanks Tyler and JewBaka!

I'd really like to find the pieces to do a steering rack swap. It's the only majorly sloppy thing that will be left after the blown shocks are swapped out. It will work just fine without swapping to a rack, but this car is entirely about the driver interaction, and a rack just offers much more connected feeling to the road for the driver than a bunch of worn out steering box stuff. I'll keep my earlids peeled.

[caption id="" align="aligncenter" width="683"]

Digging around in the engine bay I found both of these. Jammed into the engine mounts. It looks like someone kept dropping and replacing their oil caps. lol I don't know how many years this car was carrying around 3 different oil caps.[/caption]

Put a new distributor O-ring in today. It's been many years since I actually timed a vehicle myself. Don't worry, I can design 3 piece wheels to near exact manufacturing requirements, but timing an old carb'd car isn't common knowledge to me. Took a lot of fiddling around to get it to 12 degrees advance without vacuum advance plugged in. Why so tough for me?! I did some other things like tighten up the parking brake tension, adjust the wheel straight, and pack the car for tomorrow. We'll give it a try! Still have the big suspension install to go, and I've got some new parts coming too, like a racing seat and a rear sway bar. Score! Thanks Tyler and JewBaka!

I'd really like to find the pieces to do a steering rack swap. It's the only majorly sloppy thing that will be left after the blown shocks are swapped out. It will work just fine without swapping to a rack, but this car is entirely about the driver interaction, and a rack just offers much more connected feeling to the road for the driver than a bunch of worn out steering box stuff. I'll keep my earlids peeled.

[caption id="" align="aligncenter" width="683"] Today was the shakedown day. Although I didn't get a chance to get the coils in, I still took it out. It was floppy. Here's a 6am shot mixed with a 6pm shot, before and after the drift day. No action shots as of yet.[/caption]

Drift Day #1 for the car: Initial shakedown. Feb 27th, 2016

Spent some time installing a new temporary drivers seat last night, centering the steering wheel, and installing the new distributor O-ring. Didn't notice any major oil leaks on the track. Took it out for some fun laps, it was raining a bit. When the carb didn't bog down it was decent. I got some really good slides early in the day. Let a few other people putter it around, and did some teaching in some other peoples cars as well. The blown shocks and worn factory springs were predictably floppy, but in most causes it was excessive and detrimental. I've drifted some floppy cars, but the auto 3TC isn't complimentary to the 45 degrees of body roll. A cressida is more well suited to that.

Carb Bogging was my most annoying problem of the day, getting into a good groove only to have the fuel supply slosh or dry out during important throttle moment. I think I'll start a tech question thread about this as I can't have this on the school car, it needs to deliver power. Beside this and the suspension the only other problem I had mechanically was watching a student drive and the heater core blow out coolant all over my feet. RIP Heater core. Going to be a bitch to replace as they are discontinued and expensive. Sigh. I'm so broke already.

I scored a new racing seat for the car today! Hopefully the coils and seat will be ready for our first school day on March 7th. I might be forced to loop the heater lines until I find a good heater core.

The only non-car problem I'm having is who to let drive the car and for what reason. Sure everyone has something to learn, but also, some people just give me the impression it's a free ticket to beat on a car and my instruction isn't the intended use. I have to default to innocence, and if I provide a bit more of an instructional focused atmosphere it'll hopefully direct the emotional flow towards progression and learning than abuse without consequence.

Thanks to Tyler for the racing seat donation, and Warren for use of your timing light!

Another benefit of the track day that I didn't realize was a possibility, but makes sense, is all the oil pan bolts slowly backing out. Major oil leak when I checked the car today. Cool stuff! Also, along with the drippy oil pan, the power steering seals are just fukkkkkin' junk mate. Sadly, the power steering is going into the trash. To make it to the next track day I'm going to have to loop the heater core lines until I can save the $150 it is for a new one. Sigh. I expected this, and these problems, it's developing the comfort for affording them, it will come.

March 2nd 2016

RIP Power steering and heater core, both which, due to budget restraints (I've actually hit $0 in my bank account because of this venture.)

Car will be fine without both, but both were nice luxuries for people learning to operate. No more noodle arms or people with low blood pressure (Generally people who are cold.)

Looks like all the oil pan bolts actually slowly rattled themselves loose. Pretty interesting problem.

[caption id="" align="aligncenter" width="1024"]

Today was the shakedown day. Although I didn't get a chance to get the coils in, I still took it out. It was floppy. Here's a 6am shot mixed with a 6pm shot, before and after the drift day. No action shots as of yet.[/caption]

Drift Day #1 for the car: Initial shakedown. Feb 27th, 2016

Spent some time installing a new temporary drivers seat last night, centering the steering wheel, and installing the new distributor O-ring. Didn't notice any major oil leaks on the track. Took it out for some fun laps, it was raining a bit. When the carb didn't bog down it was decent. I got some really good slides early in the day. Let a few other people putter it around, and did some teaching in some other peoples cars as well. The blown shocks and worn factory springs were predictably floppy, but in most causes it was excessive and detrimental. I've drifted some floppy cars, but the auto 3TC isn't complimentary to the 45 degrees of body roll. A cressida is more well suited to that.

Carb Bogging was my most annoying problem of the day, getting into a good groove only to have the fuel supply slosh or dry out during important throttle moment. I think I'll start a tech question thread about this as I can't have this on the school car, it needs to deliver power. Beside this and the suspension the only other problem I had mechanically was watching a student drive and the heater core blow out coolant all over my feet. RIP Heater core. Going to be a bitch to replace as they are discontinued and expensive. Sigh. I'm so broke already.

I scored a new racing seat for the car today! Hopefully the coils and seat will be ready for our first school day on March 7th. I might be forced to loop the heater lines until I find a good heater core.

The only non-car problem I'm having is who to let drive the car and for what reason. Sure everyone has something to learn, but also, some people just give me the impression it's a free ticket to beat on a car and my instruction isn't the intended use. I have to default to innocence, and if I provide a bit more of an instructional focused atmosphere it'll hopefully direct the emotional flow towards progression and learning than abuse without consequence.

Thanks to Tyler for the racing seat donation, and Warren for use of your timing light!

Another benefit of the track day that I didn't realize was a possibility, but makes sense, is all the oil pan bolts slowly backing out. Major oil leak when I checked the car today. Cool stuff! Also, along with the drippy oil pan, the power steering seals are just fukkkkkin' junk mate. Sadly, the power steering is going into the trash. To make it to the next track day I'm going to have to loop the heater core lines until I can save the $150 it is for a new one. Sigh. I expected this, and these problems, it's developing the comfort for affording them, it will come.

March 2nd 2016

RIP Power steering and heater core, both which, due to budget restraints (I've actually hit $0 in my bank account because of this venture.)

Car will be fine without both, but both were nice luxuries for people learning to operate. No more noodle arms or people with low blood pressure (Generally people who are cold.)

Looks like all the oil pan bolts actually slowly rattled themselves loose. Pretty interesting problem.

[caption id="" align="aligncenter" width="1024"] Splendid Aim photography posted up a snap of my car. No actions shots to surface just yet though.[/caption]

March 3, 2016

Dang today was a long day. Started working on the car at 9am, got in the house at 12 midnight.

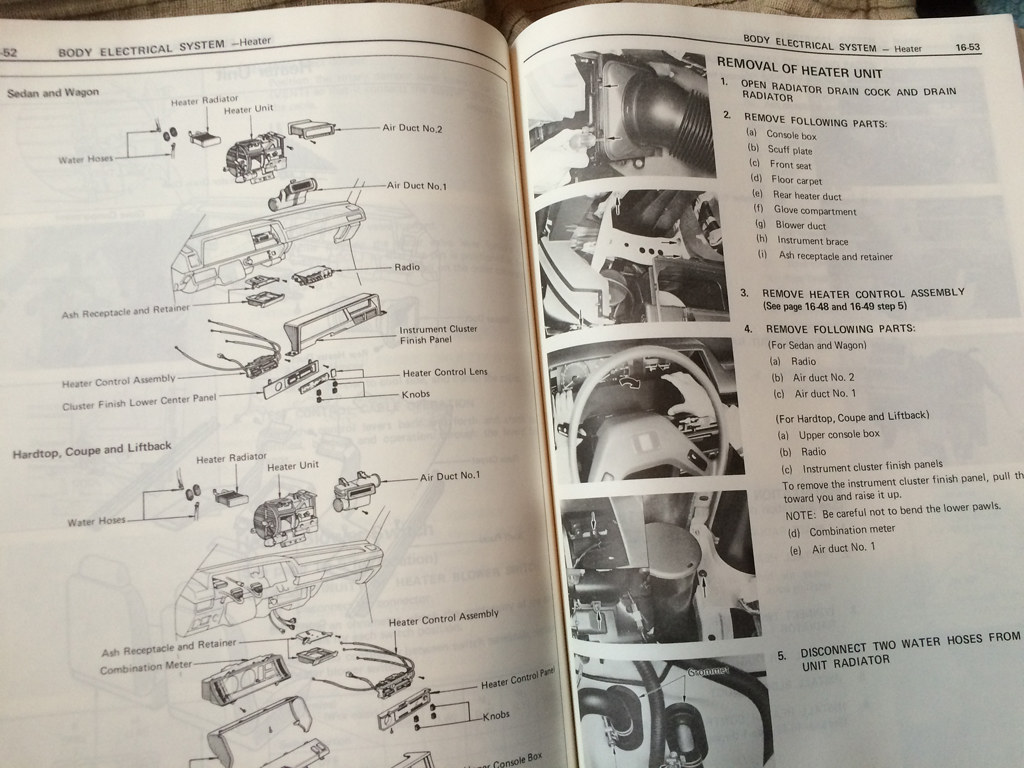

Interesting observation, the factory service manual inspires confidence. I remembered I had been displaying an '82 Corolla FSM behind my bed for like 2 years now. It'd been sitting there so long I had forgotten I owned it!

Popped that sucker open to the page about heater cores. "Looks like not as many steps as I thought it'd be. Cool!" My plan was to yank the heater core, as I looped the heater core lines last night while I was deleting the power steering.

[caption id="" align="aligncenter" width="1024"]

Splendid Aim photography posted up a snap of my car. No actions shots to surface just yet though.[/caption]

March 3, 2016

Dang today was a long day. Started working on the car at 9am, got in the house at 12 midnight.

Interesting observation, the factory service manual inspires confidence. I remembered I had been displaying an '82 Corolla FSM behind my bed for like 2 years now. It'd been sitting there so long I had forgotten I owned it!

Popped that sucker open to the page about heater cores. "Looks like not as many steps as I thought it'd be. Cool!" My plan was to yank the heater core, as I looped the heater core lines last night while I was deleting the power steering.

[caption id="" align="aligncenter" width="1024"] One page? that's all? I can hammer this out in an hour![/caption]

About halfway into removing the entire dash, I realized heater cores, no matter the bad influence of the FSM, are the automatic transmission rebuilds of interior work. ****ing screws everywhere maaaaannn...I've taken many, many dashes apart. I don't know why I forgot how ****ty it is. My estimate of an hour or two was WAY off. I was 2 hours in just getting it all apart and keeping it organized!

[caption id="" align="aligncenter" width="1024"]

One page? that's all? I can hammer this out in an hour![/caption]

About halfway into removing the entire dash, I realized heater cores, no matter the bad influence of the FSM, are the automatic transmission rebuilds of interior work. ****ing screws everywhere maaaaannn...I've taken many, many dashes apart. I don't know why I forgot how ****ty it is. My estimate of an hour or two was WAY off. I was 2 hours in just getting it all apart and keeping it organized!

[caption id="" align="aligncenter" width="1024"] Gross, rolling around in old coolant on an old carpet, yak.[/caption]

[caption id="" align="aligncenter" width="1024"]

Gross, rolling around in old coolant on an old carpet, yak.[/caption]

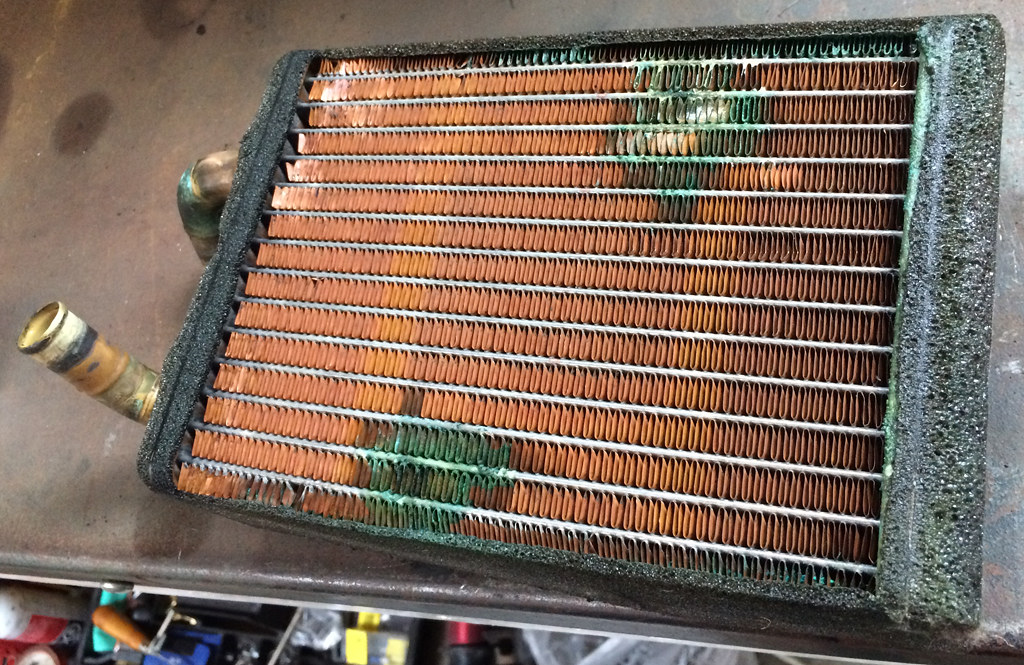

[caption id="" align="aligncenter" width="1024"] Got the core out, both inlet and outlet necks were cracked, and two holes in the fins.[/caption]

Tore the whole dash down to get a chance to see the heater core, see if it was repairable. For someone with access to a torch and practice with soldering, it might be entirely savable, but at this point I don't have the co-ordination or understanding of soldering to ensure the success I need.

So a new heater core for one of these is $148 with a great account at Lordco. There are a few people throwing ideas at me currently, but it'll be a long time before I can afford any heater core....We'll run without one for now.

I had bugged Liam the night before to come help me diagnosis some oil leaks, and try to encourage him to let me bring the car to his work. He suggested I swing by around 6pm when the shops quiet. This should be plenty of time to get the car buttoned back up and movable. At 1pm Liam called to tell me work was extremely slow and was wondering if I could bring the car in 5 hours early. ****! So I buzzed everything back together and managed to get up to his work through rush hour in 2 and a half hours.

[caption id="" align="aligncenter" width="1024"]

Got the core out, both inlet and outlet necks were cracked, and two holes in the fins.[/caption]

Tore the whole dash down to get a chance to see the heater core, see if it was repairable. For someone with access to a torch and practice with soldering, it might be entirely savable, but at this point I don't have the co-ordination or understanding of soldering to ensure the success I need.

So a new heater core for one of these is $148 with a great account at Lordco. There are a few people throwing ideas at me currently, but it'll be a long time before I can afford any heater core....We'll run without one for now.

I had bugged Liam the night before to come help me diagnosis some oil leaks, and try to encourage him to let me bring the car to his work. He suggested I swing by around 6pm when the shops quiet. This should be plenty of time to get the car buttoned back up and movable. At 1pm Liam called to tell me work was extremely slow and was wondering if I could bring the car in 5 hours early. ****! So I buzzed everything back together and managed to get up to his work through rush hour in 2 and a half hours.

[caption id="" align="aligncenter" width="1024"] All back together, sadly I didn't get the chance to clean all the disassembled parts before reinstalling.[/caption]

[caption id="" align="aligncenter" width="1024"]

All back together, sadly I didn't get the chance to clean all the disassembled parts before reinstalling.[/caption]

[caption id="" align="aligncenter" width="1024"] Liam, excited to have his soul removed by photographs[/caption]

After a heavy degreasing of the engine bay we got the car up on the hoist to take a look. What we thought originally was a loose pan, wasn't helping the case, as you could also see oil pouring from the phenolic spacer for the fuel pump. Which I had recently installed. :/ Upon removal, as predicted by Joel a while back, the spacer had developed a crack, and was trash. Luckily the shop has a basket of left over gaskets. In there was another phenolic spacer and gaskets to match!

[caption id="" align="aligncenter" width="905"]

Liam, excited to have his soul removed by photographs[/caption]

After a heavy degreasing of the engine bay we got the car up on the hoist to take a look. What we thought originally was a loose pan, wasn't helping the case, as you could also see oil pouring from the phenolic spacer for the fuel pump. Which I had recently installed. :/ Upon removal, as predicted by Joel a while back, the spacer had developed a crack, and was trash. Luckily the shop has a basket of left over gaskets. In there was another phenolic spacer and gaskets to match!

[caption id="" align="aligncenter" width="905"] Riding high, I think it's been half a decade since this car has set foot in a repair shop.[/caption]

[caption id="" align="aligncenter" width="1024"]

Riding high, I think it's been half a decade since this car has set foot in a repair shop.[/caption]

[caption id="" align="aligncenter" width="1024"] The very broken spacer. Oddly enough Liam had another just sitting around in good shape.[/caption]

[caption id="" align="aligncenter" width="1024"]

The very broken spacer. Oddly enough Liam had another just sitting around in good shape.[/caption]

[caption id="" align="aligncenter" width="1024"] Liam showing me some important tech tips.[/caption]

Next up on the list were the coils. Although the coilovers I bought from Jason would bolt onto the knuckles, the brake backing plates mounting holes on an AE86 strut, are different than an E7 strut. This created a problem, cool coilovers, but no brakes. So we chopped the bottom off each set and swapped the tops. The least amount of work, and welding. These took lots of measuring and even more mistakes, but eventually we got them back together, with some cleaned up strut top bearings, improved washer layout and disgusting rake.

[caption id="" align="aligncenter" width="975"]

Liam showing me some important tech tips.[/caption]

Next up on the list were the coils. Although the coilovers I bought from Jason would bolt onto the knuckles, the brake backing plates mounting holes on an AE86 strut, are different than an E7 strut. This created a problem, cool coilovers, but no brakes. So we chopped the bottom off each set and swapped the tops. The least amount of work, and welding. These took lots of measuring and even more mistakes, but eventually we got them back together, with some cleaned up strut top bearings, improved washer layout and disgusting rake.

[caption id="" align="aligncenter" width="975"] The two before cutting. By swapping the bottom, we don't need to shorten the tubes, as the length will already be correct! Sweet.[/caption]

[caption id="" align="aligncenter" width="1024"]

The two before cutting. By swapping the bottom, we don't need to shorten the tubes, as the length will already be correct! Sweet.[/caption]

[caption id="" align="aligncenter" width="1024"] Choppy Choppy![/caption]

By this point it was 10pm and Liam and I both wanted to go home. Still craving punishment when I arrived home, I then immediately installed the rear setup and got rid of the rear rake before heading in the house for bed....or posting on here, then bed...maybe pancakes first.

Choppy Choppy![/caption]

By this point it was 10pm and Liam and I both wanted to go home. Still craving punishment when I arrived home, I then immediately installed the rear setup and got rid of the rear rake before heading in the house for bed....or posting on here, then bed...maybe pancakes first.

Update!

Morgan popped in and had a few snaps from the previous track day!

[caption id="" align="aligncenter" width="1024"]

Update!

Morgan popped in and had a few snaps from the previous track day!

[caption id="" align="aligncenter" width="1024"] Doing some testing around learning curb.[/caption]

[caption id="" align="aligncenter" width="1024"]

Doing some testing around learning curb.[/caption]

[caption id="" align="aligncenter" width="1024"] First Unofficial student? Taking a grip line around the track. Heater core popped all over my feet on this run. lol[/caption]

March 5th 2016

Leaks update. Seems good! Liam seemed to do a rad job.

First Unofficial student? Taking a grip line around the track. Heater core popped all over my feet on this run. lol[/caption]

March 5th 2016

Leaks update. Seems good! Liam seemed to do a rad job.  The powersteering delete helped as well.

Leveled the car the other day, but never grabbed a pic. The school car is muuuuch lower now with the new setup. Looks a bit odd to me as I never have lowered cars for the most part. With some fancy wheels it'd be much sweeter than the 13x4.5jj rims currently. lolololol They actually have 4.5jj stamped on them, so you know.

[caption id="" align="aligncenter" width="1024"]

The powersteering delete helped as well.

Leveled the car the other day, but never grabbed a pic. The school car is muuuuch lower now with the new setup. Looks a bit odd to me as I never have lowered cars for the most part. With some fancy wheels it'd be much sweeter than the 13x4.5jj rims currently. lolololol They actually have 4.5jj stamped on them, so you know.

[caption id="" align="aligncenter" width="1024"] All down low. Needs another wash, including engine bay. Some fancy wheels in the future would make this baby pop. I always dream of negative offset 13" D-slots.[/caption]

[caption id="" align="aligncenter" width="1024"]

All down low. Needs another wash, including engine bay. Some fancy wheels in the future would make this baby pop. I always dream of negative offset 13" D-slots.[/caption]

[caption id="" align="aligncenter" width="1024"] Tyler Younie gave me this seat. "I tried spray painting it black, now if feels crispy." Were his words. Works for me![/caption]

Grabbed this Corbeau as a donation to the school car. This seat will change the interaction in a positive way. The factory seats, after 34 years of abuse are counter-supportive. The side bolsters now just flimsy sponges would be co-operative to flopping your body out of the seat. This new seat is much more supportive. Sadly I am unable to mount it as low as I feel it needs to be, as I am forced to keep the sliders for adaptability to different student sizes. It could be leaned back and to the right slightly more, but I did my best with an angle grinder, the original sliders, a random tub of bolts, and a bunch of steel bed frame rail a friend rescued for me.

I was stressing about monday with leaks and this seat, but really, timing and maybe an alignment should result in an awesome secondary shakedown for the new mods, as well as learning how to best put drivers into and out of the seat at our track days.

March 6th, 2016

Liam and I played with the timing a bit tonight. I might crank up the idle speed tomorrow for more gear slam. We then did some sport pulls to see how it felt.

Looking forward to finding the parts for a steering rack swap, as it'll feel WAYYYYY better with a rack. The seat and suspension massively improved the experience operating the car, which is the entire point of the car; positive feeling of operation. Lacking is the steering feel, which is ULTRA sloppy from the exploded everything in the box setup. Derek666 posted a good write up for an E7 rack swap, which was different and better than the last one I did. I'd like to find that thread at some point and start collecting the parts I need to complete it.

The car will slide around a bit in the dry if you really wiggle it, even with the auto hating life. It should be fine tomorrow with Some hand braking, donuts and small diameter slides. I don't feel it'll have the cooling issues of before with the better timing and lacking a blown heater core. Cooling system should be able to keep pressure and reduce the air being introduced. Hoping it rains, but will slide with whatever.

The big thing now is figuring out the logistics of who should be driving the car. I'd really like to limit it to the people who've come to the track with their own cars, but in a way that doesn't make sense. I'm going to play this event pretty loose and get a good feel of our first official learner day. Make some mistake and then make the next event even better.

More power will be a minor goal in the future. I want a little bit more of power over for the students, so that advanced weight transfer won't be their only focus. Looking for that casual, easy drift.

[caption id="" align="aligncenter" width="1024"]

Tyler Younie gave me this seat. "I tried spray painting it black, now if feels crispy." Were his words. Works for me![/caption]

Grabbed this Corbeau as a donation to the school car. This seat will change the interaction in a positive way. The factory seats, after 34 years of abuse are counter-supportive. The side bolsters now just flimsy sponges would be co-operative to flopping your body out of the seat. This new seat is much more supportive. Sadly I am unable to mount it as low as I feel it needs to be, as I am forced to keep the sliders for adaptability to different student sizes. It could be leaned back and to the right slightly more, but I did my best with an angle grinder, the original sliders, a random tub of bolts, and a bunch of steel bed frame rail a friend rescued for me.

I was stressing about monday with leaks and this seat, but really, timing and maybe an alignment should result in an awesome secondary shakedown for the new mods, as well as learning how to best put drivers into and out of the seat at our track days.

March 6th, 2016

Liam and I played with the timing a bit tonight. I might crank up the idle speed tomorrow for more gear slam. We then did some sport pulls to see how it felt.

Looking forward to finding the parts for a steering rack swap, as it'll feel WAYYYYY better with a rack. The seat and suspension massively improved the experience operating the car, which is the entire point of the car; positive feeling of operation. Lacking is the steering feel, which is ULTRA sloppy from the exploded everything in the box setup. Derek666 posted a good write up for an E7 rack swap, which was different and better than the last one I did. I'd like to find that thread at some point and start collecting the parts I need to complete it.

The car will slide around a bit in the dry if you really wiggle it, even with the auto hating life. It should be fine tomorrow with Some hand braking, donuts and small diameter slides. I don't feel it'll have the cooling issues of before with the better timing and lacking a blown heater core. Cooling system should be able to keep pressure and reduce the air being introduced. Hoping it rains, but will slide with whatever.

The big thing now is figuring out the logistics of who should be driving the car. I'd really like to limit it to the people who've come to the track with their own cars, but in a way that doesn't make sense. I'm going to play this event pretty loose and get a good feel of our first official learner day. Make some mistake and then make the next event even better.

More power will be a minor goal in the future. I want a little bit more of power over for the students, so that advanced weight transfer won't be their only focus. Looking for that casual, easy drift.

[caption id="" align="aligncenter" width="1024"] Being an idiot the evening before our first school day.[/caption]

March 7th, 2016. First official school day.

Didn't get a chance to grab pictures of everyone who drove the car, but it was a successful day not only for the car, but the event as well.

From the school cars perspective, the only hiccups were a little bit of sloshing, which seemed associated to to high heat soak after many laps. The other was a popped lower rad hose, which Matt and Warren helped me solve at the end of the evening.

The Learner focused day was new to us. We've done lots of teaching, but often mixed in with the advanced and expert crowd. It was for the most part self moderated by these learner drivers. We had multiple stages laid out. Beginning with simple hand brake turns, new drivers had the rare chance to just fling their cars around without worry. No police or angry neighbors, no other drivers or pedestrians, just themselves in a safe learning space.

From donuts they could move up to the figure 8 area, an area which could also double for really big donuts. After mastering these it was a simple skip to the back corner of the track to try out the Peanut learner layout which has transitions and hairpins to play with, and a few different lines to drive through it.

Last and the most intimidating was the Kidney bean, located on the corners 1 & 2 of the big oval. It was a slightly higher speed course with a few curbs and walls to miss.

As planned, you could watch drivers begin the night struggling with donuts. Myself or one of our many other volunteering staff would sit with them, instruct a few simple pointers and watch the slides improve. Throughout the night drivers were moving stations as their skills and confidence grew, by the end of the night almost all the drivers who's cars didn't break were doing decent slides on the most difficult layout, the kidney bean. It was only Mechanical woes that slowed the others down.

The school car drove really well. I was unable to appease all the requests for people to drive it, I did my best at balancing my budget, the cars health, and offering learning opportunities for others, while assessing what future improvements might work best.

Thanks to all the people that volunteered, and most importantly, the good attitudes and well behaved learners!

[caption id="" align="aligncenter" width="791"]

Being an idiot the evening before our first school day.[/caption]

March 7th, 2016. First official school day.

Didn't get a chance to grab pictures of everyone who drove the car, but it was a successful day not only for the car, but the event as well.

From the school cars perspective, the only hiccups were a little bit of sloshing, which seemed associated to to high heat soak after many laps. The other was a popped lower rad hose, which Matt and Warren helped me solve at the end of the evening.

The Learner focused day was new to us. We've done lots of teaching, but often mixed in with the advanced and expert crowd. It was for the most part self moderated by these learner drivers. We had multiple stages laid out. Beginning with simple hand brake turns, new drivers had the rare chance to just fling their cars around without worry. No police or angry neighbors, no other drivers or pedestrians, just themselves in a safe learning space.

From donuts they could move up to the figure 8 area, an area which could also double for really big donuts. After mastering these it was a simple skip to the back corner of the track to try out the Peanut learner layout which has transitions and hairpins to play with, and a few different lines to drive through it.

Last and the most intimidating was the Kidney bean, located on the corners 1 & 2 of the big oval. It was a slightly higher speed course with a few curbs and walls to miss.

As planned, you could watch drivers begin the night struggling with donuts. Myself or one of our many other volunteering staff would sit with them, instruct a few simple pointers and watch the slides improve. Throughout the night drivers were moving stations as their skills and confidence grew, by the end of the night almost all the drivers who's cars didn't break were doing decent slides on the most difficult layout, the kidney bean. It was only Mechanical woes that slowed the others down.

The school car drove really well. I was unable to appease all the requests for people to drive it, I did my best at balancing my budget, the cars health, and offering learning opportunities for others, while assessing what future improvements might work best.

Thanks to all the people that volunteered, and most importantly, the good attitudes and well behaved learners!

[caption id="" align="aligncenter" width="791"] Just a few of the people who got a chance to take a rip and get some instruction on how to slide.[/caption]

[caption id="" align="aligncenter" width="1024"]

Just a few of the people who got a chance to take a rip and get some instruction on how to slide.[/caption]

[caption id="" align="aligncenter" width="1024"] The culprit of the cooling system pressure loss was this Alternator, lower rad hose combo. Both not OEM, resulting in some lazy tolerances. With the cooling system pressure now running 16psi, and the hoses being old and soft, during a corner I think I managed to flop the motor over just enough for the alternator to nick the hose. Warren helped me find a better shape OEM hose (better clearance) so I could make it home.[/caption]

The culprit of the cooling system pressure loss was this Alternator, lower rad hose combo. Both not OEM, resulting in some lazy tolerances. With the cooling system pressure now running 16psi, and the hoses being old and soft, during a corner I think I managed to flop the motor over just enough for the alternator to nick the hose. Warren helped me find a better shape OEM hose (better clearance) so I could make it home.[/caption]

[embed]https://youtu.be/xDpI8GmYGhQ[/embed] Matt Selter manages to grab a video of me doing some test laps near the end of the night. Ultimately I blew the lower rad hose on this run.

Some grippier fronts will make the future a bit better. I'll be on the hunt for some sticky skinny fronts, like a 185 autocross tire or something of that nature. Steering rack conversion would be the ultimate in the future!!!!!

hi , this is just amazing , i would like to know what other mods have yo made to your racing rolla , keep the good work!